The mixed accessory packaging machine has become a key equipment for improving production efficiency and reducing labor costs with its high efficiency, precision and flexibility. It can accurately measure and evenly mix accessories of different types and specifications to achieve diversified packaging. The machine has high-precision metering function and uses advanced sensors to accurately measure the number of various accessories to ensure accurate packaging. Whether it is hardware such as screws and nuts, or electronic components and furniture accessories, they can be customized according to specifications and packaging requirements. Whether it is bagged, boxed or bottled, the equipment can flexibly adjust the packaging form and material, and is widely used in hardware manufacturing, mechanical processing, electronic appliances, furniture and other industries. In terms of after-sales service, equipment suppliers provide installation guidance, commissioning and operator training, and most equipment has a one-year warranty and lifetime maintenance service. With the advancement of industrial automation, the mixed accessory packaging machine plays an important role in improving production efficiency and packaging quality. In the future, it will develop in the direction of intelligence and flexibility, bringing higher benefits and competitiveness to enterprises.

The main technical paramete:

| Name | Mixed accessories packaging machine |

| Production capacity(bag/min) | 2--5 |

| Measuring range(Kg) | 2--6 |

| Bag making forms | Back to seal |

| Total power(KW) | 4 |

| Weight(Kg) | 1500 |

| Power supply voltage | 220V 50-60HZ 380 50HZ |

| Bag size(mm) | Length: 150-400 Wide:150-250 |

| Packaging materials | Composite membrane materials |

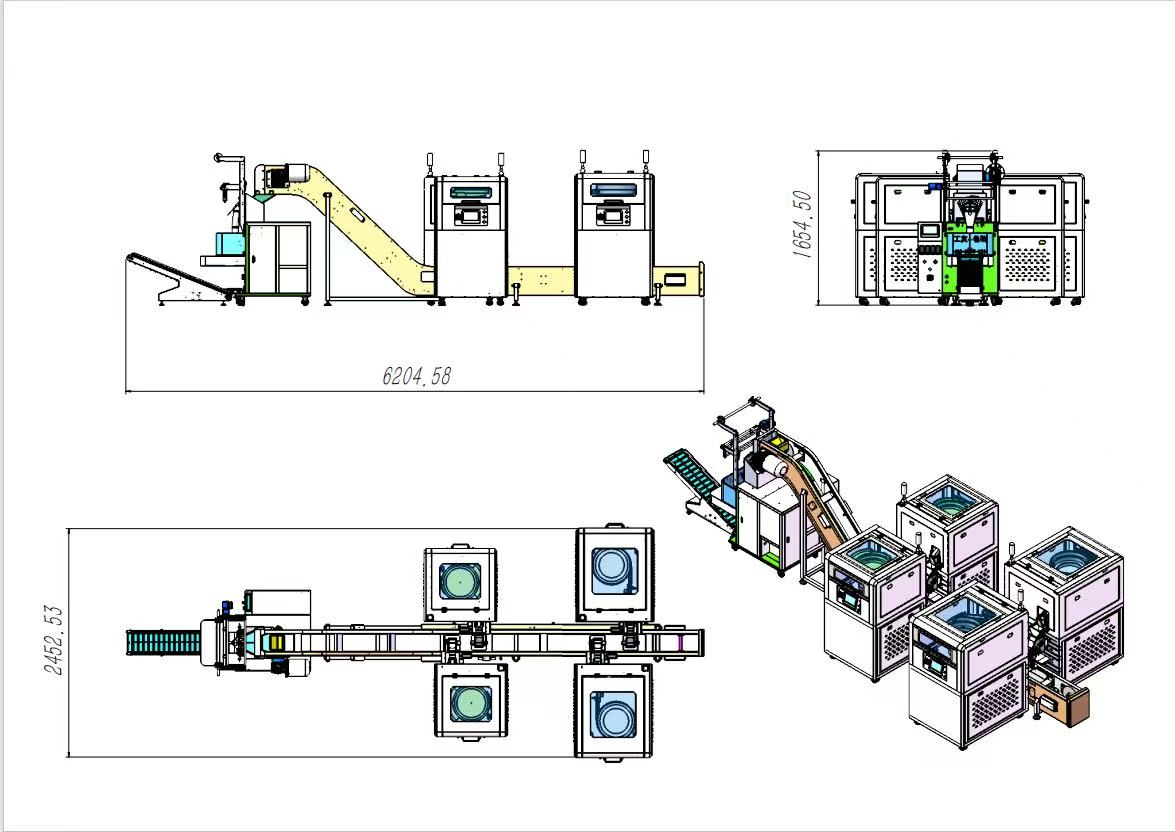

| Dimensions(mm) | 6204 x2452 x1654 |